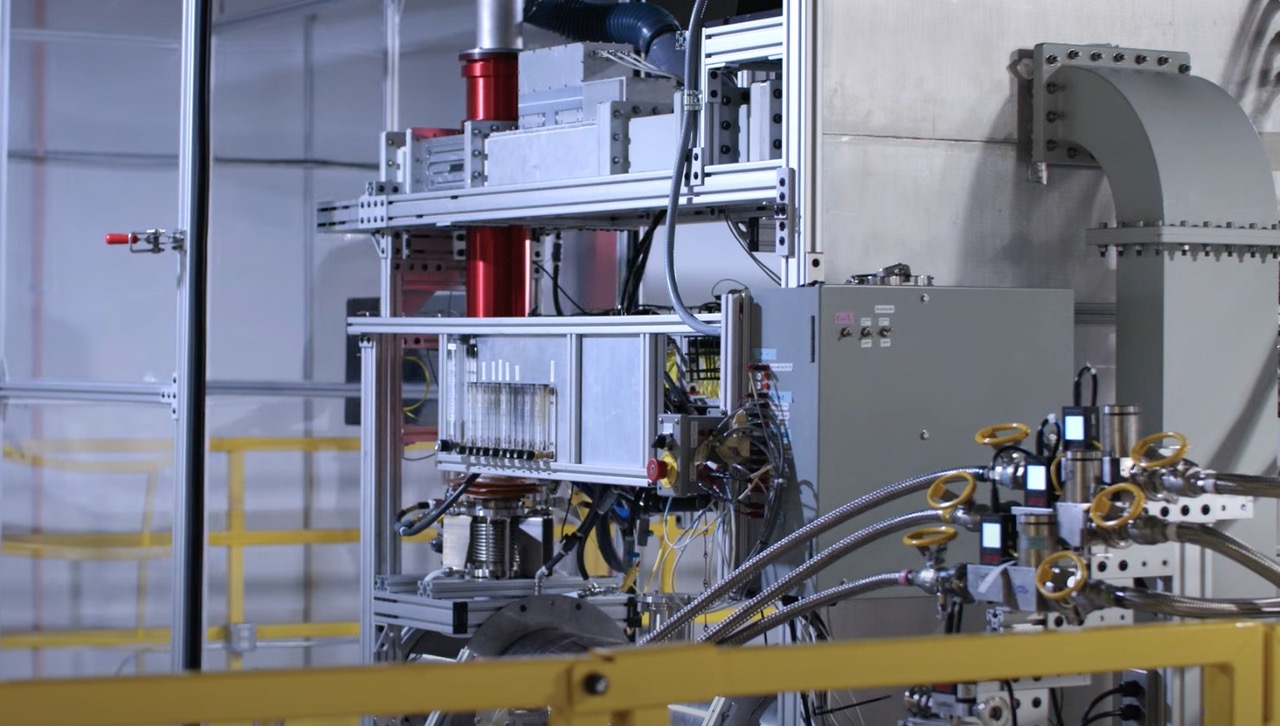

Transform Materials’ plasma technology can use any hydrocarbon source -- whether refinery off-gas, cracker tail-gas, stranded butane, or any other problem streams. No combustion is involved. Instead, our microwave-generated plasma energizes hydrocarbon streams to form clean acetylene and hydrogen.

We achieve this without CO2 generation, without any carbon solids, and without any catalysts required.

Transform's technology offers a substitute for coal-based acetylene production for clients who use acetylene today for feedstock. This provides a new pathway for producing acetylene that eliminates reliance on legacy coal and intricate supply chains. Clean and worry-free.

+ Clean: Zero CO2 and zero waste generated

+ Energy efficient: 99% microwave energy utilized

+ Automated: Self-cleaning, continuous process

+ High product yield: Full utilization of all carbon

+ Safe, by design: Rapid startup and shutdown

+ High purity products: No by-products generated

Recognizing the global reach of its technology, Transform presently has twenty-seven pending US and foreign patent applications and six issued US patents. Our patent filings are ongoing to protect technical innovations and commercial endeavors.

"The Project with Transform Materials is one of the most significant transformations in our company history."

--Toshio Imai, CEO of Denka